BENDING CELLS

A robotic bending cell is an advanced automated system that integrates a press brake with a 6- or 7-axis robot, designed to perform all standard bending operations, from picking flat parts and bending the workpiece to unloading the finished part.

The main advantages of a robotic bending cell are:

• It improves operator safety by automating repetitive and dangerous tasks.

• It reduces costs by eliminating human errors and reducing waste.

• It works without supervision and for longer hours or shifts.

• It improves the ability to predict and estimate processing times.

The TK FLEXIBEND CELL by Schiavi Macchine represents a revolutionary concept in bending automation, combining a press brake with a robot in an integrated system. The 7-axis robot, available in different models, moves horizontally on a rail fixed to the ground, with a maximum length of 19 meters, offering exceptional flexibility in movement and operation. Designed to handle a wide range of parts, the TK FLEXIBEND CELL consistently maintains a high and constant level of quality.

TK FLEX BEND CELL

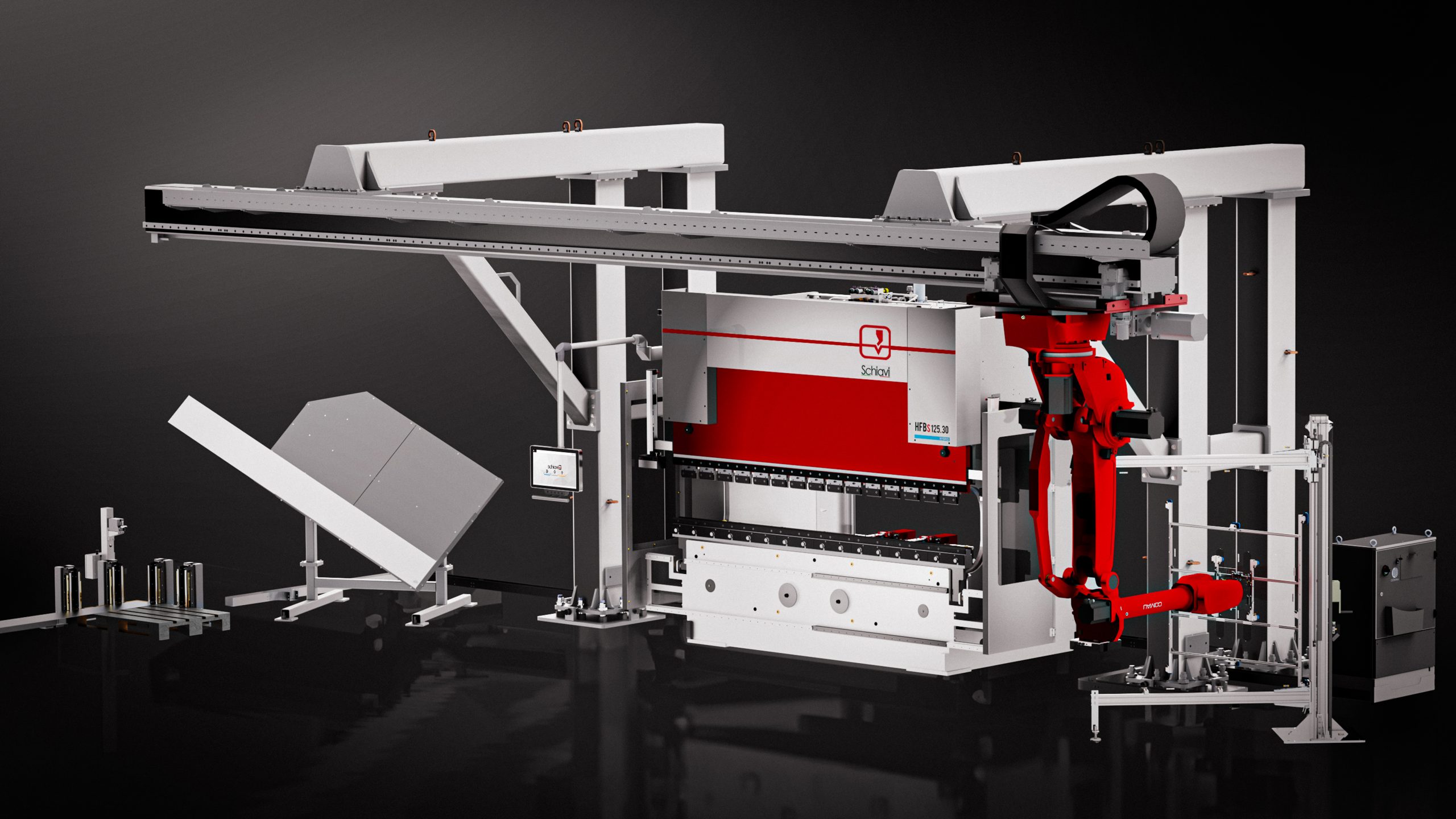

Schiavi Macchine’s TK MEGABEND CELL is a revolutionary solution designed to take the automatic bending cell to the next level. Equipped with COMAU 6-axis NJ 60-2.2 or NJ 110-3.0 robots and a supplementary overhead axis (7th axis) with a variable length from 6 to 11 metres, the MEGABEND CELL optimises the use of space, leaving the area in front of the press brake free for other cell components or for stacking products.

The TK MEGABEND CELL is designed to be combined with hydraulic or hybrid Schiavi press brakes. This configuration allows the use of larger, more powerful press brakes with the same flexibility as a standard bending cell, offering the possibility to switch to manual production when required.

tk mega bend cell

The Schiavi Macchine TK MINIBEND CELL is an innovative and compact solution for automating the bending of small and medium-sized parts, guaranteeing maximum efficiency, precision and flexibility. This space-saving design cell is equipped with standard components that ensure high productivity and quality:

The mini cell is equipped with the latest COMAU robot model. Designed for Industry 4.0 and Industry 5.0-ready, the TK MINIBEND CELL supports intelligent and connected production. Programming is completely offline, directly in the office. This drastically reduces the need for interventions on the machine and allows a fast and efficient transition between different products required by production.

tk mini bend cell