press brakes

Schiavi Macchine International’s hydraulic and hybrid press brakes are the best solution for sheet metal bending and metal carpentry processing. Our range consists of the press brakes: LineAr, Hfbx, Hfbs, Bsts that ensure precision bending, production speed and easy implementation in the production process.

Each Schiavi Macchine International press brake can be customized according to the specifications required by the customer.

The LineAr is the top of the Schiavi range: a press brake that revolutionizes the world of bending by eliminating the canoe effect with an internationally patented solution that keeps the tool holder tables perfectly horizontal and parallel, ensuring an absolute linearity of the profile.

The LineAr is especially recommended for those who require maximum precision of interlocking profiles or to facilitate subsequent procedures such as welding or manual and robotic assembly. LineAr is a synonym of speed, top quality and strong bending force.

The LineAr range varies from 3 m 130 ton to 12 m 1200 ton.

Linear

Schiavi HFBx press brakes represent the most versatile model in automated bending processes. High performance: approach and return speed up to 250 mm/s.

Complete flexibility: I’ts extremely high performance is characterised by a large stroke (500 mm) and span of 800mm(up to 1000 mm upon request). The wide span between the tables makes the production of large-sized boxed sections possible while maintaining a high processing speed. The HFBx has been designed to facilitate the withdrawal and removal of complex profile parts and is particularly suitable for robotic solutions.

HFBX

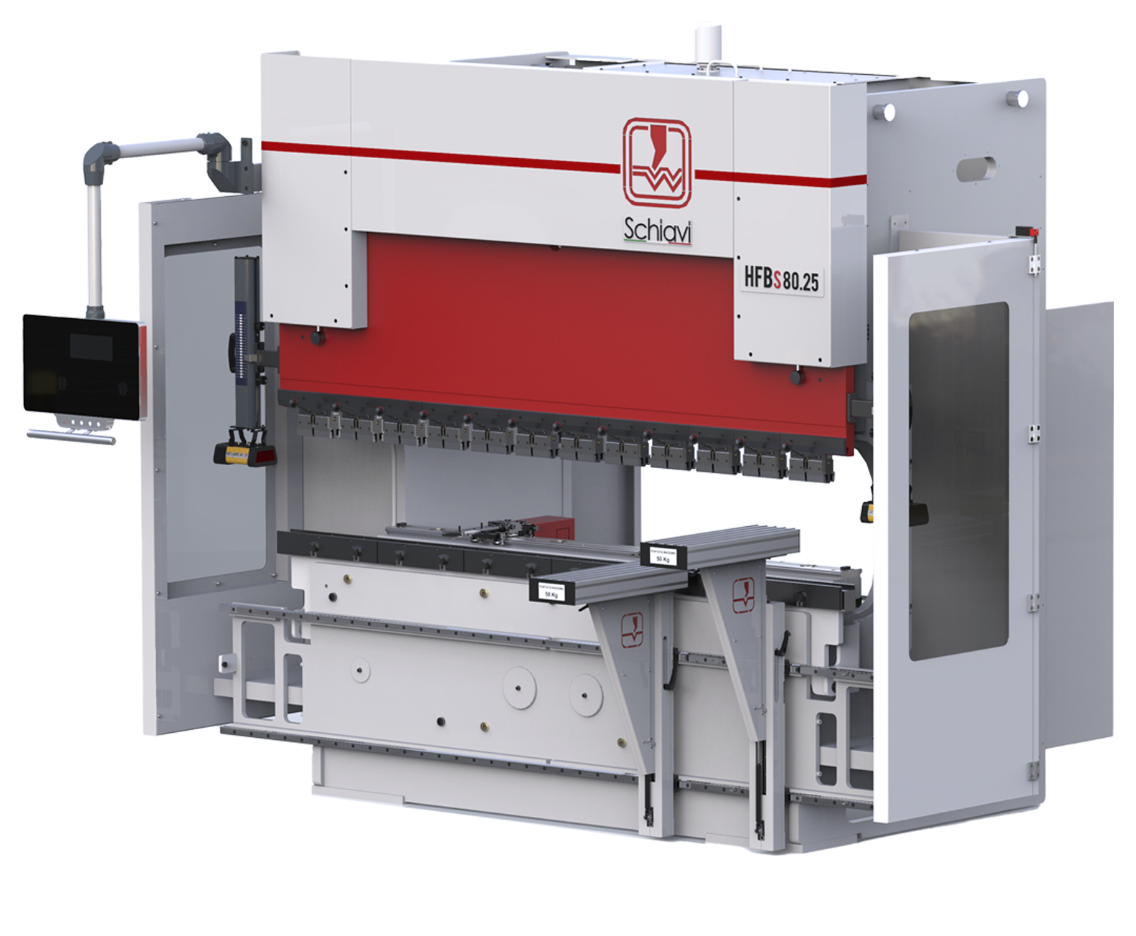

The HFBs press brake is the perfect solution for customers who require impeccable bending accuracy and large-scale production. HFBs ensure high versatility and flexibility with excellent results in the production of different thickness sheet parts. The HFBs model, combined with special hydraulics and state of the art software, offers companies operating in sheet metal machining the perfect means for increasing their competitiveness.

HFBS

The BSTs range guarantees safety and flexibility in a competitive package. The range has been designed for simple and fast bending but also offers the accuracy and constancy synonymous with the Schiavi name. Equipped with rear mechanics (X-R) and a dedicated Task SK12 CNC, the models range from 500 kN – 1.2 metres to 1250 kN – 4 metres.

BSTS