NUMERICAL CONTROLS, SOFTWARE,

CNC & DRIVERS

Task Dynamic offers a variety of advanced controls for managing various machine functions. The offering includes both simple controls, which allow for the determination, storage and control of the parameters required to perform the bending task, and more sophisticated control panels, with advanced graphical interface and bending simulation.

Schiavi Macchine International’s proprietary software is developed to improve the efficiency and accuracy of manufacturing operations. In 1984, Schiavi founded the Task software division for in-house development of bending software, numerical controls and PLCs, thus ensuring complete control over every stage of production and offering state-of-the-art tools at all times.

Today, Schiavi Macchine offers two advanced software solutions, Titano and Athena, each designed to meet specific needs and ensure maximum performance of your plant, optimizing production processes and ensuring high performance.

TITANO

The Robust Solution for Upgrading Dated Presses

Titano is our most proven numerical control software designed specifically for upgrading dated presses. Ideal for those seeking a robust and reliable platform, Titano gives new life to older machines, making them versatile and powerful in managing production operations. With its intuitive interface and advanced features, it is the preferred choice for optimizing complex processes, improving efficiency and extending the life of existing presses.

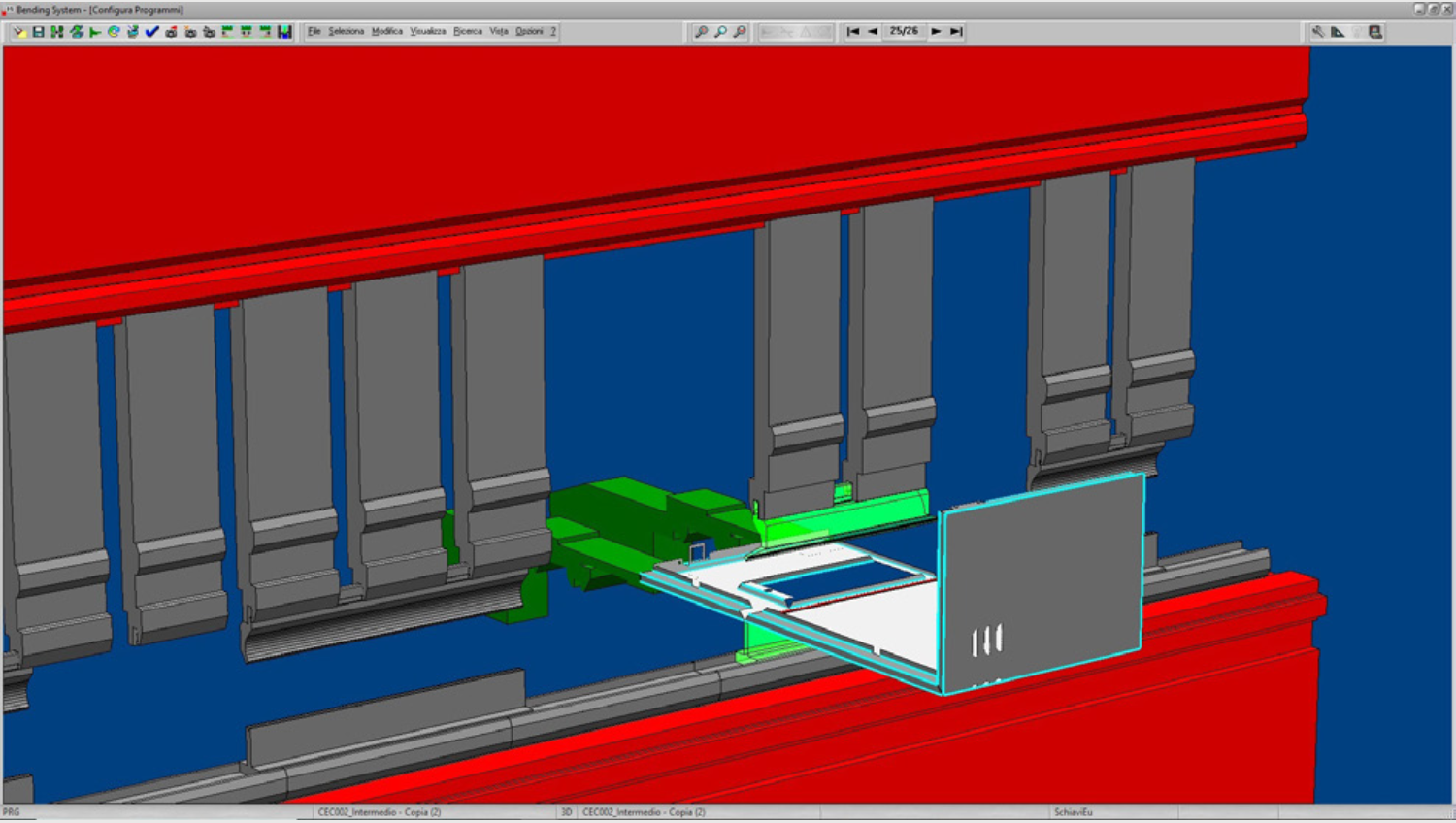

ATHENA

Integrated Production Management and Innovation in Scheduling

Athena represents a significant advance in industrial production management and optimization. This innovative product functions as both a numerical control and offline software, offering a complete solution to monitor, analyze and optimize every step of the production process in real time. With its ability to identify and resolve bottlenecks and inefficiencies, Athena ensures a smoother and more effective workflow, improving overall productivity.

Designed with detailed 3D simulation and a highly intuitive user interface, Athena simplifies and makes machine scheduling more accurate. Ideal for those who want to maintain total control over their production processes, Athena ensures the highest quality in final products by allowing operations to be visualized and scheduled both in real time, directly on the machine, and off-line, without interrupting production.

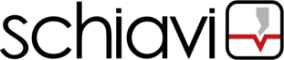

A.R.S.

It is the proprietary software for simulation and programming of robotic islands that can calculate the correct trajectories to allow robots to complete the processes of loading, bending and unloading the component.

GENERAL FEATURES

Automatic calculation of optimal trajectories

6-axis, 7-axis gantry, 7-axis track robot management

Configurable work cells

Collision management

Program generation for robot controller

Multi-language management

Configurable unloading program

Manually editable program

Automatic gripper change

Multi-stack loading

“Easy to use” interface

Full integration with bending software

Integrated gripper editor with multiple configurations

(suction cup, gripper, suction cup + gripper)

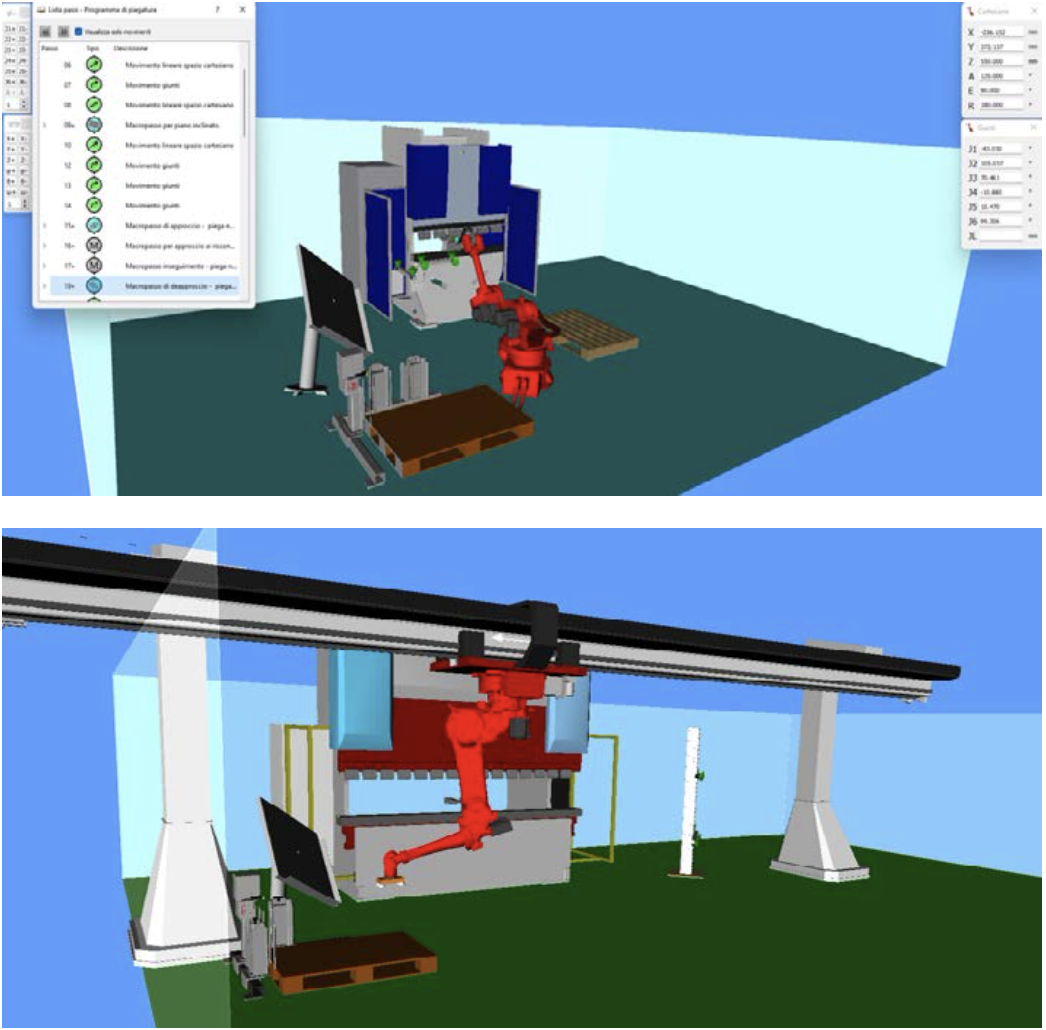

BENDING SYSTEM

It is the most advanced Schiavi Macchine office software, powerful and easy to use. It generates the bending sequence, tool configuration, bending program and correct part development (useful for the cutting process) in a very short time. All this can be sent to production via the company server. Bending System with its A.R.S. application can simulate the position of the gripper for the robot.

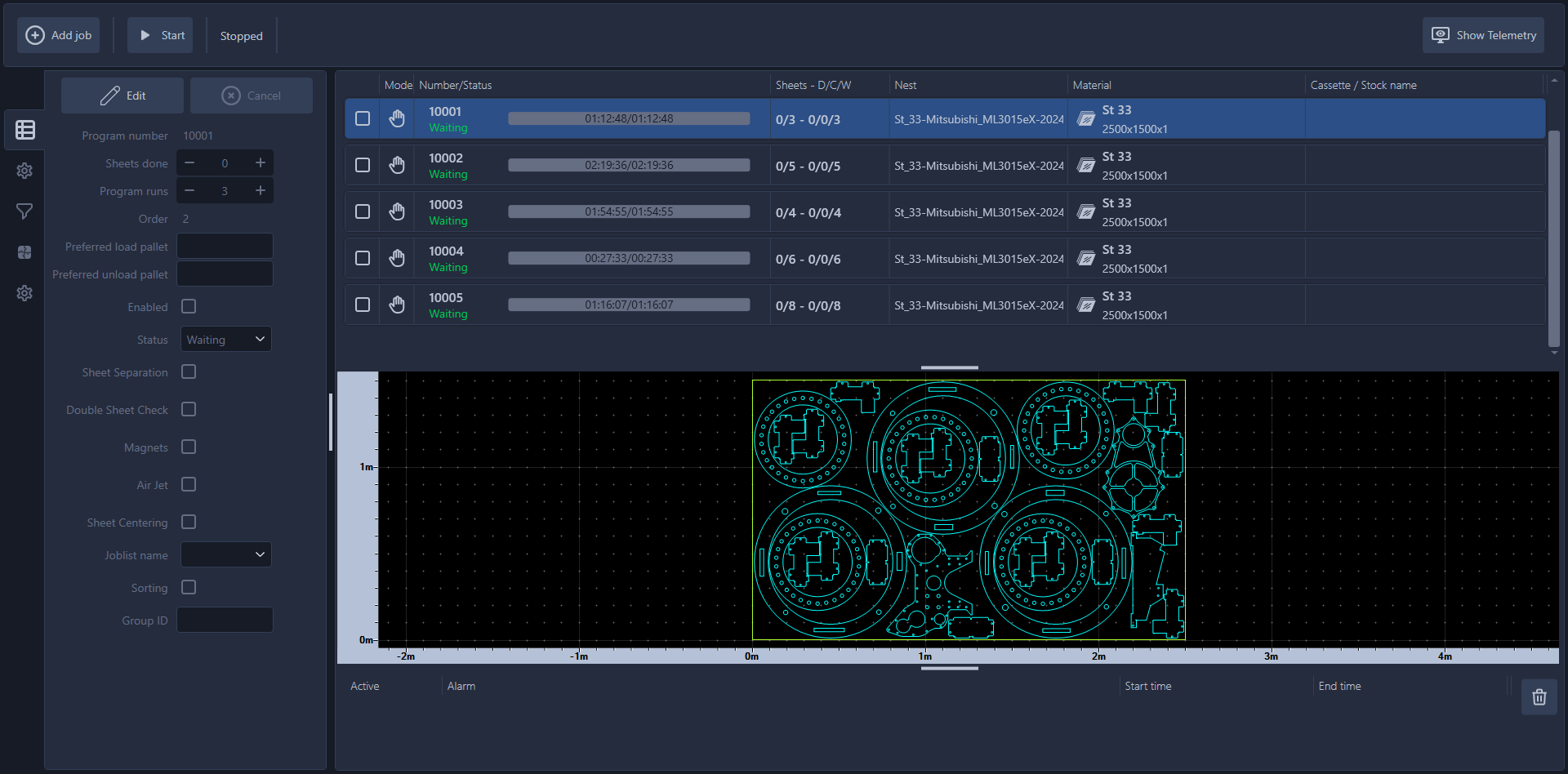

ORIONIX

The complete solution for laser management, automation and sorting.

The Orionix Laser Automation Module is an innovative platform designed to manage and optimize the entire production process, from individual sheet metal to finished and cut parts. This software offers seamless integration of laser, automation and sorting systems for a linear and coordinated workflow.

CNC AND DRIVERS

CRC3 is the device for managing all the tasks required to control the press brake devices in real time. CRC3 communicates with the numerical control and allows all axes of the press brake to be driven.

EMBLAX is a compact solution that integrates motor and drive into a single product, allowing a reduction in footprint, cost and simplification of wiring. EMBLAX is easy and immediate to parameterize: diagnostics via PC is provided by a monitoring program that has a very useful real-time oscilloscope function.