TASK AUTOMATION

CUSTOM AUTOMATED SYSTEMS AND SERVO SYSTEMS FOR PRESS BRAKES AND LASER CUTTING MACHINES

Task Dynamic, the division of Schiavi Macchine International specialising in advanced, customised solutions for industrial automation, is known for its specific focus on sheet metal processing solutions. We have decades of experience under our belt and aim to optimise production processes and increase the efficiency of our customers’ operations.

VISION & MISSION

Innovation and Italian Manufacturing Quality

For more than 60 years, Schiavi Macchine has been bringing the excellence of Italian manufacturing to the world. Our ongoing commitment to innovation and research and development makes us a leader in sheet metal automation solutions.

Custom Solutions for Efficiency

We offer customised, technologically advanced machinery, designed to optimise each stage of production, to our customers. At Schiavi, quality and efficiency go hand in hand for real, guaranteed results.

A Family-Run, Visionary Team

Schiavi Macchine is a family-run business, founded on the sound values of mutual respect, responsibility and dedication. The third generation of the Zinetti family now runs the company with the enthusiasm and expertise that have always characterised the family history, continuing to innovate and carrying on a tradition of excellence that is expressed in every project.

Global Expansion, Italian Roots

With over 14,000 machines installed and a growing global presence, we aim to export Italian excellence worldwide. Our mission is to supply cutting-edge solutions and keep Italy at the centre of industrial technological innovation.

The COMPACT SERVER is a space-saving solution for loading/unloading metal sheets. Designed for quick and easy installation, the system is pre-assembled at the factory and is delivered ready to be added to the laser machine to slash start-up time. A ready-to-use machine, perfect for customers looking for immediate efficiency.

FEATURES

– Fast transport and assembly, one truck only.

– User-friendly programming via PLC.

– Thickness monitoring device included (not optional).

COMPACT SERVER

The COMPACT TOWER is a modular automation solution for loading, unloading and storing metal sheets. It is configurable, meaning that it can grow with the customer’s needs and adapt to a variety of production scenarios.

MAIN FEATURES:

– Configurable with drawers at different heights, with or without platform.

– Non-slip forks to avoid scratching delicate materials.

– Three-position pallet changing system to optimise the production cycle.

COMPACT TOWER

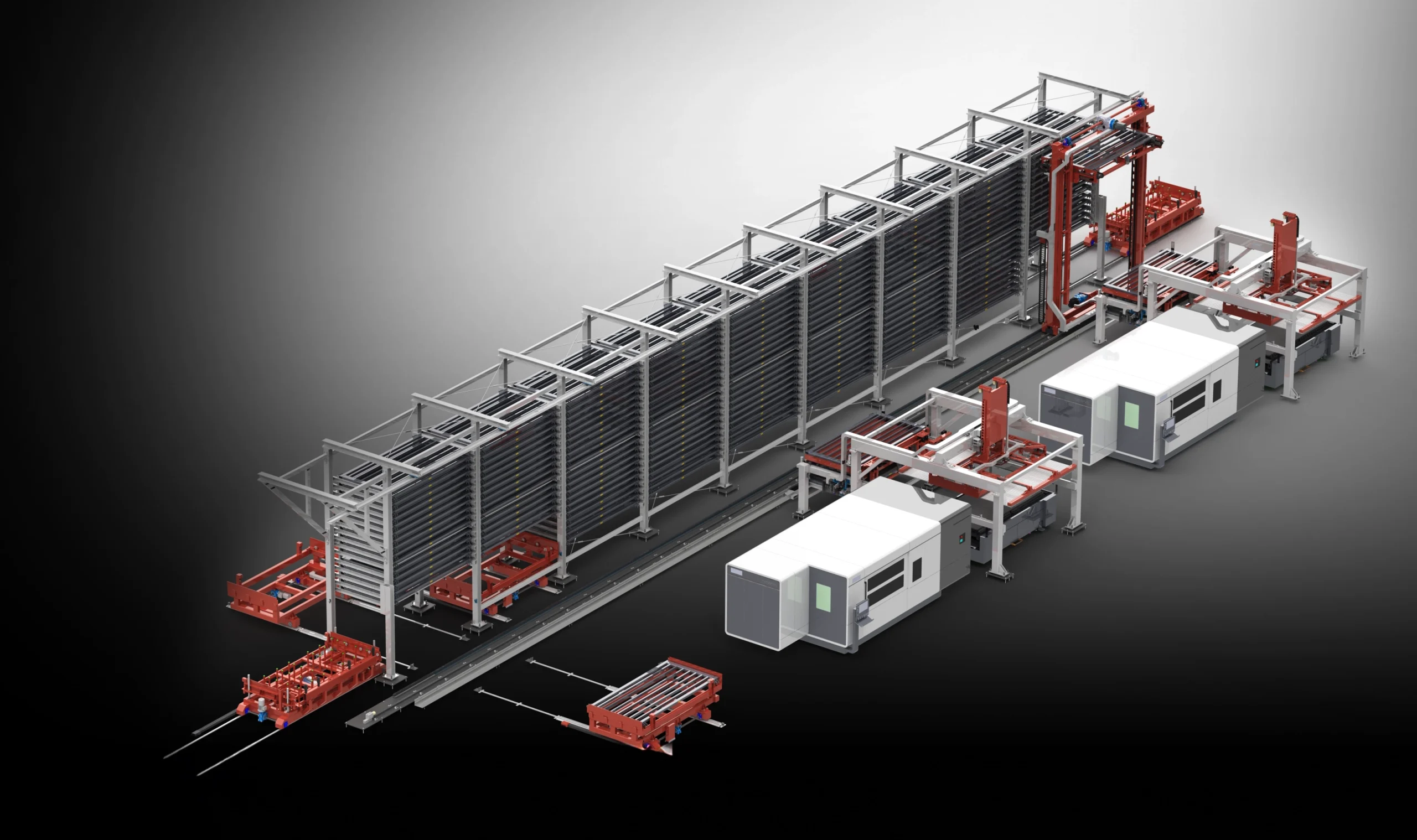

The automated storage and retrieval system is at the heart of the handling operations. It picks and places drawers to and from the respective locations and in the loading/unloading bays of the laser and sorting machine.

Once loaded with unfinished material, the system can run independently for a long time carrying out autonomous operations, such as calling the required drawer to the loading/unloading station, delivering a drawer complete with processed sheets, or changing drawers for different processes.

MULTI TOWER

Integrated Production Management and Innovation in Programming

Athena is a significant advancement in industrial production management and optimisation. This innovative product works both as a CNC and as off-line software, offering a complete solution to monitor, analyse and optimise every step of the production process in real-time. Being able to identify and solve bottlenecks and inefficiencies, Athena ensures a more streamline and effective workflow to the benefit of overall productivity.

Designed with a detailed 3D simulation and a very user-friendly interface, Athena makes machine programming easier and more accurate. It is ideal for customers who wish to maintain total control over their production processes. Athena guarantees the highest quality end products, allowing operations to be displayed and programmed directly on the machine in real time and off-line, without interrupting production.

ATHENA

BENDING SYSTEM is the most advanced office software by Schiavi Macchine, powerful and easy to use. It generates the bending sequence, tool configuration, bending program, and the correct flat pattern development (useful for the cutting process) in a very short time. Everything can be sent to production via the company server. Bending System, with its A.R.S. application, is capable of simulating the gripper position for the robot.

A.R.S. is the proprietary software for the simulation and programming of robotic cells, capable of calculating the correct trajectories to allow robots to complete the process of loading, bending and unloading of the component.

SOFTWARE

CRC3 is the device to manage all the necessary activities to control the bending press devices in real time. CRC3 communicates with the numeric control and enables piloting of all the bending press axes.

EMBLAX is a compact solution that integrates motor and drives in a single product, reducing overall dimensions, costs and simplifying the wiring. Setting the EMBLAX parameters is easy and immediate: diagnotics via PC is ensured by a monitoring program that has a very useful oscilloscope function in real time.

PLC and drives

The Schiavi Macchine automatic tool changer in versions TXP and TXP2 is the 4.0 system that ensures a total automation of tooling time. The TXP system, perfectly integrated with the Schiavi software, allows the operator to receive bending programs from the office, carry out fast and precise tooling in automatic mode. With TXP machine down times caused by the normal machine set-up are drastically reduced. TXP automatically manages the rotation of the punches and uses standard tools.

With TXP2 it is possible to serve two press brakes with a single stock, highly optimizing costs and space.

Txp e txp2